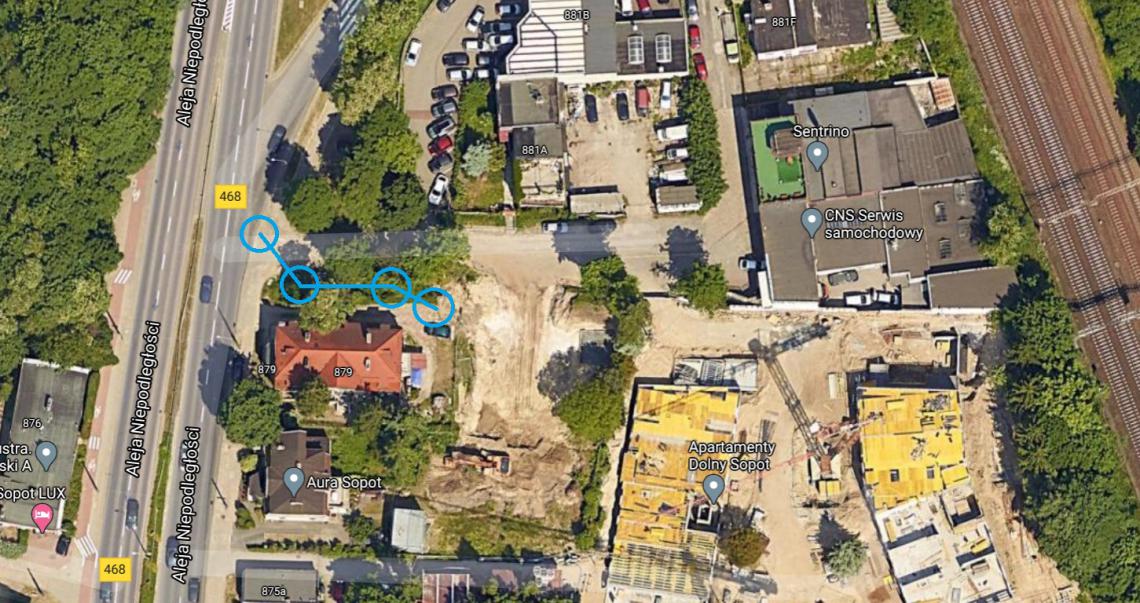

As part of the project to build a multi-family residential building, located in Sopot, Al. Niepodległości, commissioned by Korporacja Budowlana DORACO in Sopot, a gravity sewer was installed.

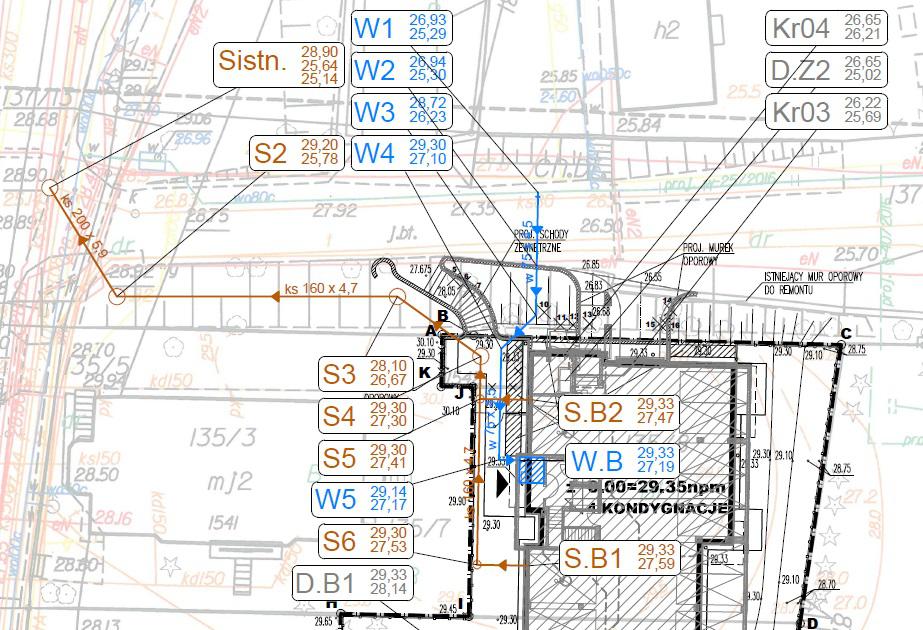

The installation was to connect the existing sewage wells and consisted of three sections:

-

the first section from the Sistn manhole to the S2 manhole, sewer with the use of PP225 modular pipes with a total length of 9.5 meters

-

the second section from the S2 well to the S3 well, sewer with the use of Ø160 PE pipes welded, with a total length of 21 meters

-

the third section from the S3 well to the S4 well, sewer with the use of Ø160 PE pipes welded, with a total length of 8 meters

Originally, it was assumed that only the first two sections would be made using the Gravity Drilling technology, i.e. from Sistn to S2 and to S2 to S3. The Investor planned to make the third section using a different technology. However, after getting acquainted with the possibilities, quality of work, time-consumption and costs, he decided that he would also entrust the implementation of the third section of the installation with the technology using the Gravity Drilling Rig. Why was the Gravity Drilling technology chosen for this project? First of all, the installation, through the beginning located in the Sistn well, covered the area of a very busy roadway connecting the cities of Sopot and Gdynia. The use of any other technology, whether trench or trenchless, would involve closing traffic on the entire two-lane highway in the direction of Gdynia and its fork leading to the Car Showrooms and nearby residential areas.

The use of the technology of Gravity Drilling has made it possible to install this section of the sewerage system completely non-invasively into the existing infrastructure, by pulling in a section of PP225 pipes constructed from segments of Modular Pipes, from the Sistn well to the S1 well where the Gravity Drilling Machine was installed.

Further stages of installation using other technologies would require the dismantling or replacement of the existing S2, S3 and S4 wells. This would significantly hamper other construction works related to the facility and significantly increase the cost of the sewage system. The very limited amount of space was essential for this construction. The use of other trenchless technology, would make it difficult if not impossible to conduct other work while the sewer is being installed.

In the case of this installation, the choice of the trenchless technology with the use of the Gravitational Drilling Rig was the most favorable, from the economic point of view, and also for other reasons: reduction of social costs resulting from the nuisance to the environment of the installation works carried out, non-invasiveness for other construction works related to the facility, reduction of exhaust emissions and broadly understood ecology.