Installation: Construction of a sanitary sewage connection to the building of the former Bank of Poland, converted into restaurant and hotel functions.

Location: Gdynia, Poland

Construction conditions: very difficult

Technical data of installation:

| Installation siameter: | 225 mm |

| Installation Length: | 26 mb |

| Gravity drop: | 1% |

| Installation Depth: | ok. 3 m ppt |

Originally, it was planned to perform the installation using the excavation method.

It turned out that it will be quite difficult to implement this installation in such a way, mainly due to the location of the installation under the surface in the existing passage - gate passage, narrow and lined with historic paving stones.

It would be necessary to dismantle the pavement almost completely and dismantle the asphalt belonging to the street, along with the adjacent concrete pavement. It would also be difficult to excavate the installation at a depth of about 3 meters in the gateway. After completing the installation, the existing condition of the pavement should of course be restored. The trench installation has been abandoned. Instead, various variants of implementation using trenchless technologies have been considered. Drilling technology using auger drilling machines and microtunnelling were considered. However, devices designed for these technologies require starting chambers of 3 meters and more of length. Therefore, it would be necessary to demolish the existing starting well, along with a part of the asphalt surface, and restore it to its original state after completion of the works.

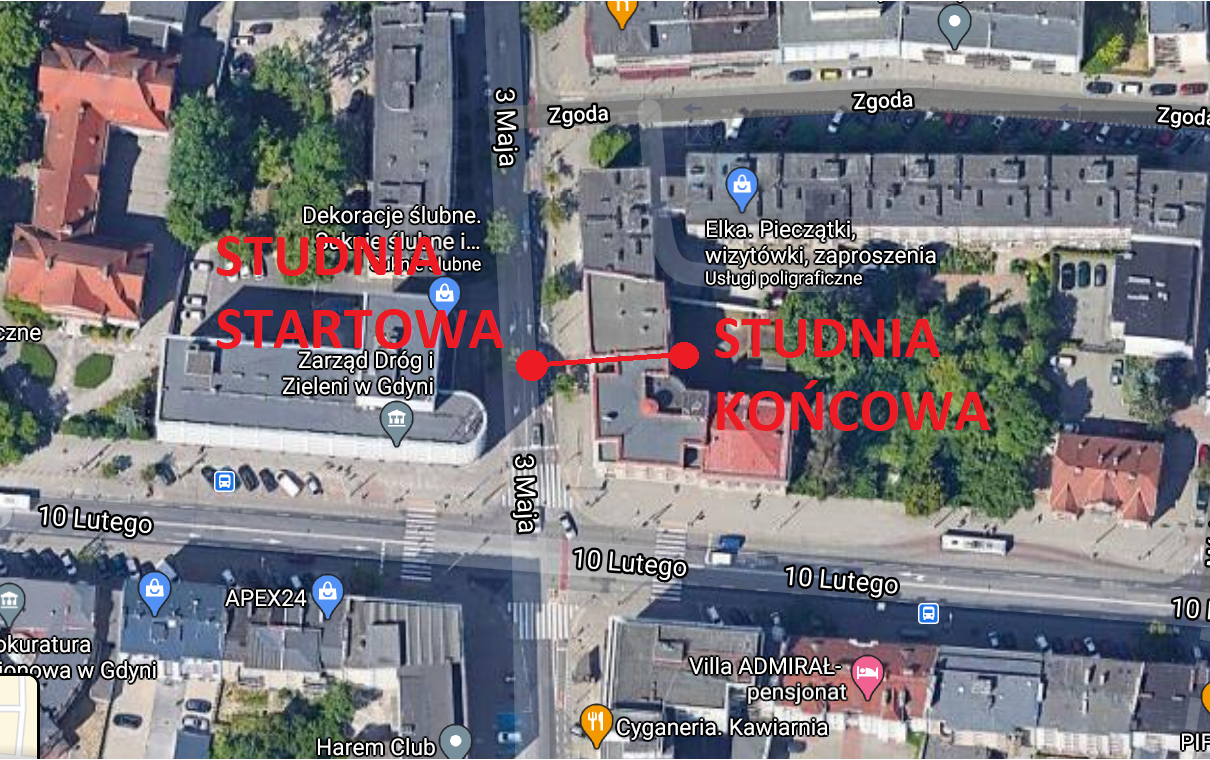

Traffic on 3-Maja Street would also have to be stopped for the duration of the work. In addition, local foundations for existing buildings were expected. This would make it difficult to drill through them, while maintaining the desired slope, using the mentioned trenchless technologies. Any interference with the existing pavement is not only a problem with the need to recreate them and close traffic for the time of installation. Once damaged, the road surface will never return to its original condition. The broken cohesion and continuity of the surface, despite the use of even the most modern technologies to restore it, will require periodic repairs forever. In places where the pavement is violated, hollows and cracks will appear over time. Especially after the periods of fall, winter and spring rains and frosts. The ideal solution was to use the MIDO technology and the Gravity Drilling Rig. This technology made it possible to perform the installation using a completely trenchless method, without any interference with the existing infrastructure. The drill rig is installed in the launch well, without removing any of the well components and without even the slightest interference with the existing road surface. First, a pilot drilling was made from the starting well, located at 3-Maja Street, to the ending well.

Our drilling technology, using specialized drilling tools, along with a highly accurate positioning and locating system, allowed us to complete the installation with a preset 1% slope, maintaining high precision along the entire length of the 26-meters installation. Warto wspomnieć, że technologia MIDO, pozwala na wysoką precyzję wiercenia, sięgającą nawet 0,2%.

After reaching the final well with the pilot head, the drilling head was converted in the well with a reamer and the first segment of the modular pipe. Then, by pulling the head back into the starting well, the installation was realized by adding more pipe modules.

Performing this installation using excavation methods would be an estimated three to four times more expensive. In order for the work to be excavated with safety conditions for the building, a sealed wall would have to be installed at the entrance to the building's courtyard. The height of the roof of the entrance to the yard is 2.9 meters, which would make it much more difficult or even impossible to secure the excavation itself along the planned installation. Execution with excavation technology would therefore pose a threat to the safety and even life of employees. The use of the Gravity Drilling technology has also contributed to a significant reduction in the time of making this installation. All the works, including preparatory works, with the use of trenchless technologies and the Gravity Drilling Rig, took less than nine hours. In the case of excavation methods for this installation, we estimate that the work would take about a week. For a few days it would be necessary to close the road on which the starting well is located. In addition, the excavation work would mean stopping other works related to the renovation of the building, e.g. scaffolding and facade renovation. The technology of Gravity Drilling did not affect the implementation of other works related to the facility. The only obstacle for the surroundings was the exclusion of one lane from traffic for a few hours.