The ready-to-work set consists of a COMPACT DRILL SET IN A CONTAINER CONSTRUCTION

CONTAINER WITH OUR GRAVITATIONAL DRILLING SYSTEM

Our innovative equipment allows a high level of precision while performing gravity sewer installations. The technology of gravity sewer drilling does not require pit excavation and allows drilling in all ground conditions even in the presence of groundwater.

Advantages:

- SMALL DIMENSIONS - Installation of the machine through a DN 600 manhole

- TOTALLY TRENCHLESS - Horizontal drilling begins and ends in the well

- PRECISION - Installation with an accuracy of 0,2%, using a remote control and radiolocating system

- NO DRAINAGE IS REQUIRED - Installation in places where groundwater occurs

- DRILLING AT EVERY DEPTH - Building the sewer at the very bottom and under the well cover

- NO NEED TO BLOCK THE SEWER - work on active sewage collectors

- WORKING IN WELLS WITH LOW MECHANICAL STRENGTH - construction of installations from any type of existing well

The kit includes:

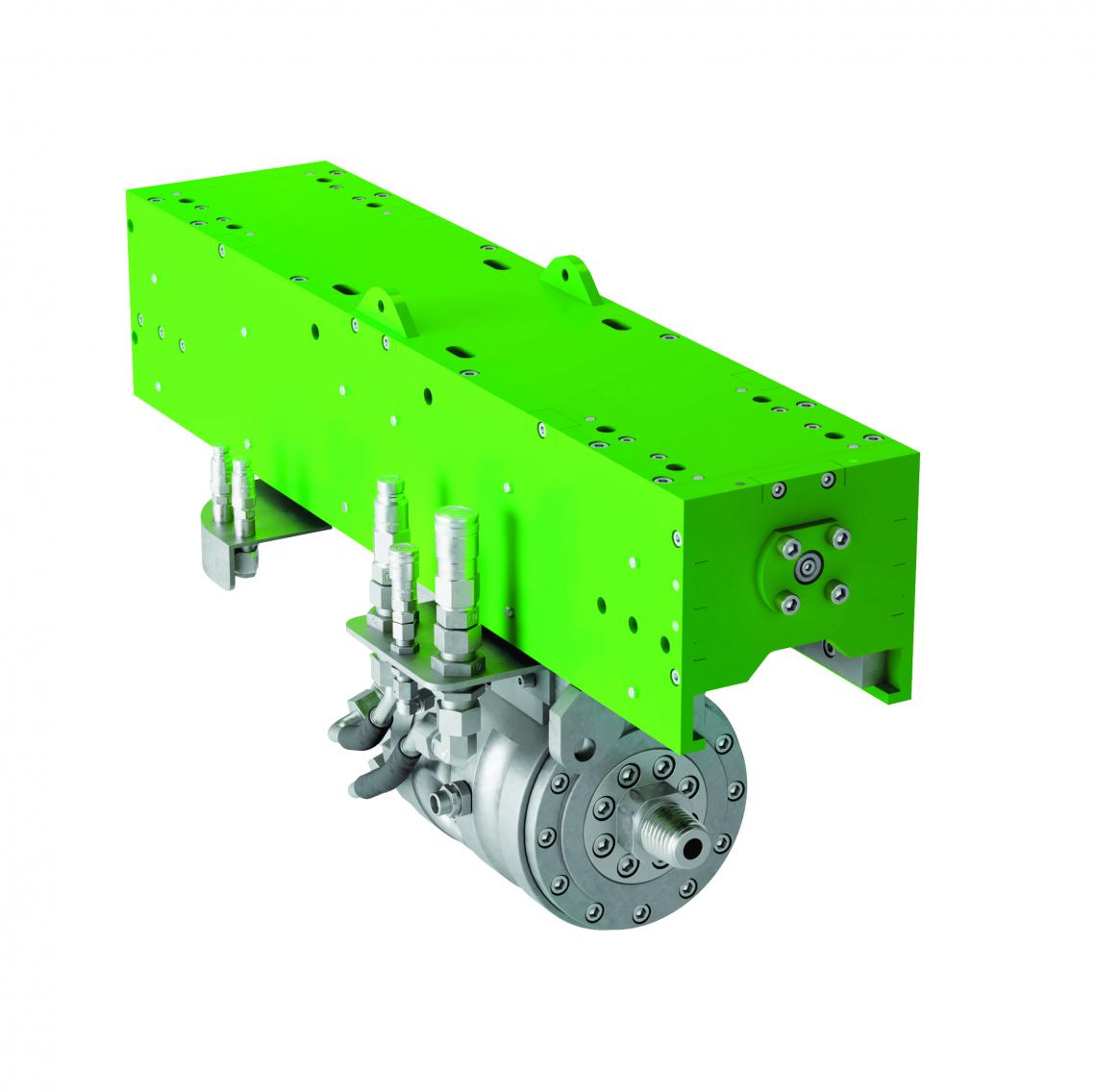

DRILLING RIG

Technical parameters:

- Max. thrust force: 90 kN

- Max. pullback force: 90 kN

- Stroke length: 670 mm

- Feed speed: 50 mm/s

- Max. torque: 1100 Nm

- Max. rotation speed: 350 rpm

- Max. hydraulic pressure: 250 bar

- Dimensions: 1070 x 330 x 555 mm

- Drilling rig weight: 330 kg

- Starting sewage well diameter: Ø 1200 mm (47″)

- Pipe/drilling rod length: 700 mm / 550 mm

- Drilling rod diameter: Ø 76 mm (3″)

- Max. pipe diameter: Ø 500 mm (20″)

DRILLING RIG TRANSPORT STAND

Enables safe transport of the gravitational drilling rig and fastens its elements.

MOUNTING RIMS

The standard rims are esigned for mounting the machine in a DN 1200 well with the possibility of adjusting the size (in the case of a well deviating from the standard diameters). We also offer larger diameters such as DN 1500 and DN 1800.

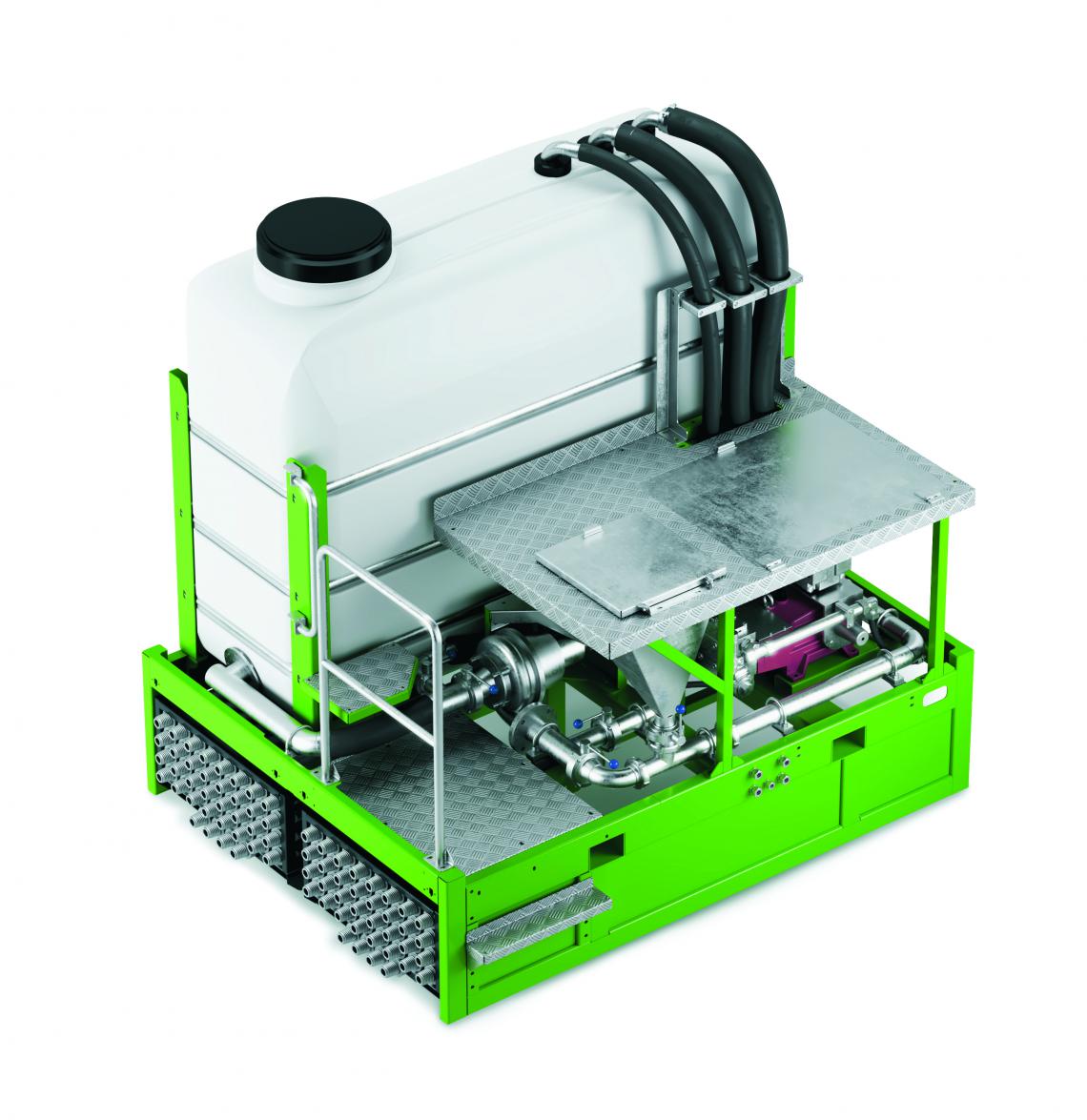

HYDRAULIC UNIT

Radio controlled, diesel powered with one pump, one regulator and proportionally controlled distributors powering all functions of the drilling rig and the bentonite flush unit.

Technical parameters:

- Deutz diesel engine, liquid cooled, 55.6 kW,

- Hydraulic supply parameters: max. pressure of 250 bar, max. flow of 120 l/min,

- 250 l oil tank (oil included),

- 250 l diesel fuel tank,

- Remote control system,

- Emergency stop switch operated via a remote control even from the sewage well.

REMOTE CONTROL TRANSMITTER

The drilling set is equipped with a waterproof radio remote control unit allowing the control over the entire drilling process.

Parameters:

- Ergonomic design makes it possible to work in difficult conditions.

- The device controls 14 functions.

- The remote control transmitter is paired with the hydraulic power pack.

BENTONITE FLUSH UNIT

Powered by the hydraulic power unit, it features a mixing tank and an integrated unit for flushing the system and a tank for the drilling fluid.

Technical parameters:

- Tank volume 2000 l

- Jet mixing system

- Drilling fluid max. flow: 160 l/min

- Drilling fluid max. pressure: 80 bar

- Remote controlled

DRILLING RODS

A typical set includes 36 drill rods.

Technical parameters:

- Rod length: 550 mm

- Rod diameter: Ø 73 mm (2.9″)

- Custom rack for 36 rods

SET OF REAMERS

The set includes reamers for the diameter range of dedicated modular pipes:

- Ø 180 mm (7.1″)

- Ø 225 mm (8.8″)

- Ø 280 mm (11″)

- Ø 315 mm (12.4″)

- Ø 400 mm (15,8″)

- Ø 500 mm (19,6″)

Reamers are equipped with a swivel.

WATER-SEALING SYSTEM

The water-sealing system makes it possible to drill in places where groundwater occurs and additionally stabilizes the rods.

REMOTE CONTROL AND RADIOLOCATING SYSTEM MAG-8

Advanced device characterized by manufacturing precision and an interference-resistant 3D Faraday antenna. Ability to work in 10 frequencies and to switch between high and low power. Easy to use interface. Allows a larger distance from the transmitter and descending deeperthan ever before. Easy switching between operating modes. Gold-plated electronic modules and a powerful DSP processor ensure reliable operation. 2-in-1 locating system, acting as two independently tracking locators to ensure better accuracy and reliability.

Technical parameters:

- Frequency range: 10 frequencies, 4 kHz – 31 kHz

- Water Resistance: IP 65

- Temperature range: from -20 °C to 60 °C

- Telemetry: 4 radio channels with range up to 90 m

- Lithium battery pack: 12.5 V

- Battery life: max. 50 h

- Dimensions: 680 x 130 x 300 mm

- Weight: 3 kg

HYDRAULIC CRIMPER FOR MODULAR PIPES

A set of dedicated devices makes it easy to join modular pipes. The set includes a hydraulic power pack, a joining tool and a wired control unit. Compressive force of about 45 kN guarantees permanent connection.

Technical parameters:

- The set of joining tools for modular pipes, matching the range of available pipe diameters

- Length of the hydraulic hoses for the hydraulic power pack 12 m

- Length of the hydraulic hoses of the crimper 0,3 m

- Cable length wired remote control 12 m

- Crimper connectors FF ISO 6,3 G1/4 M

- Hydraulic power pack connectors FF ISO 6,3 G1/4 F

- Working pressure 160 bar

- Oil flow 2 l/min

- Weight of the crimper (depending on the size) from 12 to 24 kg