Common trenchless technologies

Trenchless technologies are constantly gaining new application areas. Among the offers of machines for their implementation, we have equipment for horizontal jacking, all kinds of worm drills and microtunneling devices on the market. We have access to very precise hydraulic jacking machines and HDD drilling rigs. It can be assumed that the market of equipment for the implementation of underground installations using trenchless methods allows for the implementation of all underground installations, in particular in situations and places where traditional excavation technologies would cause difficulties for the environment or would be impossible due to the existing building conditions. There are, however, such projects, the execution of which with commonly known and used trenchless machines and technologies is difficult or even impossible to be fully trenchless. These include precise gravity installations, in which the main parameter is maintaining straightness along the entire length and a specific, very precise angle in relation to the level, called gravity slope. This decrease is precisely calculated by the sewer network designer. The lack of its implementation during construction prevents the proper functioning of the entire sewage network. Such installations include all sewer and retention connections and sewer interconnections. A particularly difficult case of such installations, where the disadvantages of typical trenchless machines and technologies are clearly visible, are installations connecting existing sewage manholes: typical DN 1000 or DN 1200 or other non-standard ones. Such installations can be described as the most difficult to implement and the most demanding. In such situations, there is no chance of a complete installation with trenchless technology, taking into account commonly available trenchless technologies. Typical machines, which can meet the given precision and allow for effective overcoming obstacles in the ground, require starting chambers larger than the cubature of a typical sewer well. Therefore, it becomes necessary to partially dismantle the existing infrastructure: usually a sewage well and a fragment of the adjacent area, which is usually the surface of a road or pavement.

Gravity Drilling Rig

To perform such installations 100% trenchless, the Gravity Drill has just been developed. This device and the technology of horizontal directional drilling, known as the technology of Gravity Drilling, was developed precisely in order to make all such installations fully trenchless, without the need for any interference with the existing infrastructure, in particular road infrastructure.

For more than twenty years, the MIDO company has been undertaking the implementation of such difficult installation cases, using all commonly available equipment and technologies. Unfortunately, the equipment was sometimes unreliable, but most of all its limited capabilities did not allow for proper execution of the projects undertaken. Therefore, at the beginning of their activity in the field of construction of underground installations, the employees for the implementation of subsequent installations developed and used a self-developed, at first defective and imperfect machine, called the Duct Drilling Machine. Years of practice and resulting machine modifications have refined this technology to perform even the most demanding installation tasks without problems. The Gravitational Drilling Rig and the Gravity Drilling Technology were created. These names are related to precise, gravity sewage installations.

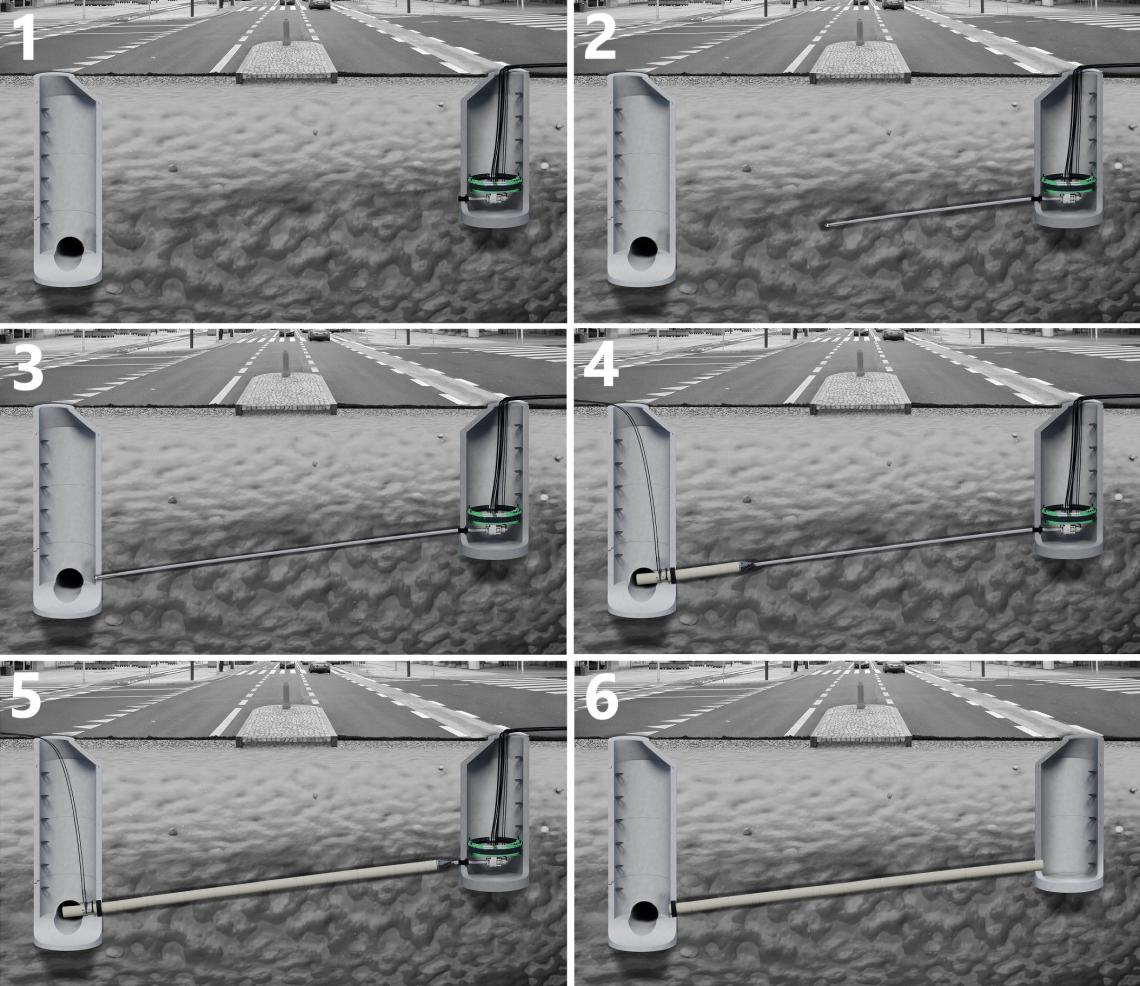

The undoubted advantage of the Gravity Drilling technology is the possibility of making installations between the existing sewage wells, without the need to disassemble any elements in their vicinity. Work only takes place between the starting well and the ending well. The illustration below shows schematically the stages of building an underground installation using the Gravity Drilling Rig.

The only nuisance for the surroundings is the necessity to exclude from traffic the lanes in which these wells are located. This is a very important feature. In the case of other trenchless technologies, the implementation of a gravity installation between the existing wells involves significant interference with the surroundings and most often the necessity to exclude the entire road, running and adjacent to the wells participating in the construction, from traffic. Another feature that distinguishes the Gravity Drilling technology is the ability to overcome any hard obstacles that may occur in the ground along the drilling route. None of the other available technologies, allows like the Gravity Drilling Rig, to maintain precision, straightness and the set gravitational drop in difficult ground conditions, when drilling encounter hard obstacles in the form of pebbles, concrete elements or debris. An extremely important feature, related to the ability to overcome obstacles while drilling, is the very precise gravity fall. We can make sewage systems with an accuracy of 0.2%, which is unattainable in the case of other trenchless technologies.

Gravity Drilling Technology - a handful of advantages

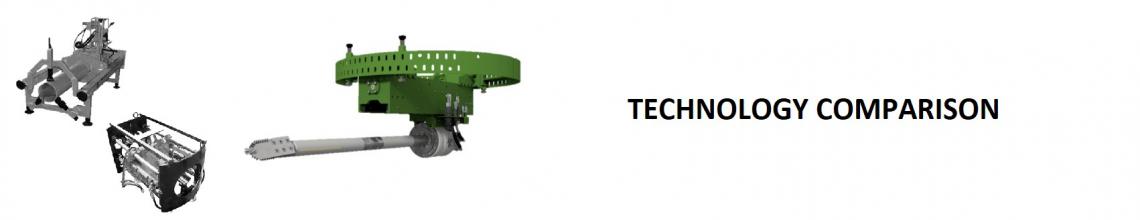

By comparing the Gravity Drilling technology developed by MIDO to other currently available, popular, typical and commonly used trenchless technologies in the field of horizontal directional drilling, we ensure:

1. Reduction of costs and time up to 1/4 of the original value, compared to the execution with the use of excavation technologies.

We avoid costly and long-term works related to the organization of construction and excavation works.

2. Cost and time reduction to half the value compared to other trenchless technologies.

The use of other trenchless technologies would involve partial disassembly of the existing wells and pavement elements in the area of these wells.

3. No traffic difficulties caused by excluding the streets and sidewalks in the immediate vicinity of the construction site.

4. Certainty of achieving the specified, even very precise gravitational gradient of the installation being built.

An example of the above-mentioned features and advantages can be one of the installations made by MIDO:

Or other projects made by MIDO using the Gravity Drilling technology:

Also worth reading:

Comments: gravity drilling rig - innovative trenchless technology