This is one of the most common myths — "the shorter, the easier."

In trenchless technology, it is the opposite.

On a very short bore run, every millimetre matters. Why?

1. No room to adjust the bore path

On a long bore you can correct direction during drilling.

On a short run — the margin for error is practically zero.

2. Large grade over a short distance

A grade of, for example, 7% over 8 metres means the entire correction must fit within a very short span.

This requires extreme precision in pilot steering.

3. Dense nearby infrastructure

The shorter the run, the more congested the surroundings tend to be:

utility cable conflicts, existing pipes, foundations, curbs, manholes.

4. Inability to deploy full-length guides

Sometimes there is no space in the pit or excavation to set up the equipment in an optimal position — which further complicates maintaining geometry.

5. Every centimetre off-axis risks missing the receiving pit

On an 8-metre run a 1 cm error is a significant deviation.

On a 40-metre run — the same centimetre is much less consequential.

Racibórz is a town with a long history and a distinctive geological profile. A place where the Odra River has shaped the urban layout for centuries, and beneath the surface lie layers of river gravels, cobbles and sands. These conditions mean every underground project requires experience and technology that enable reliable, quiet work without disruption.

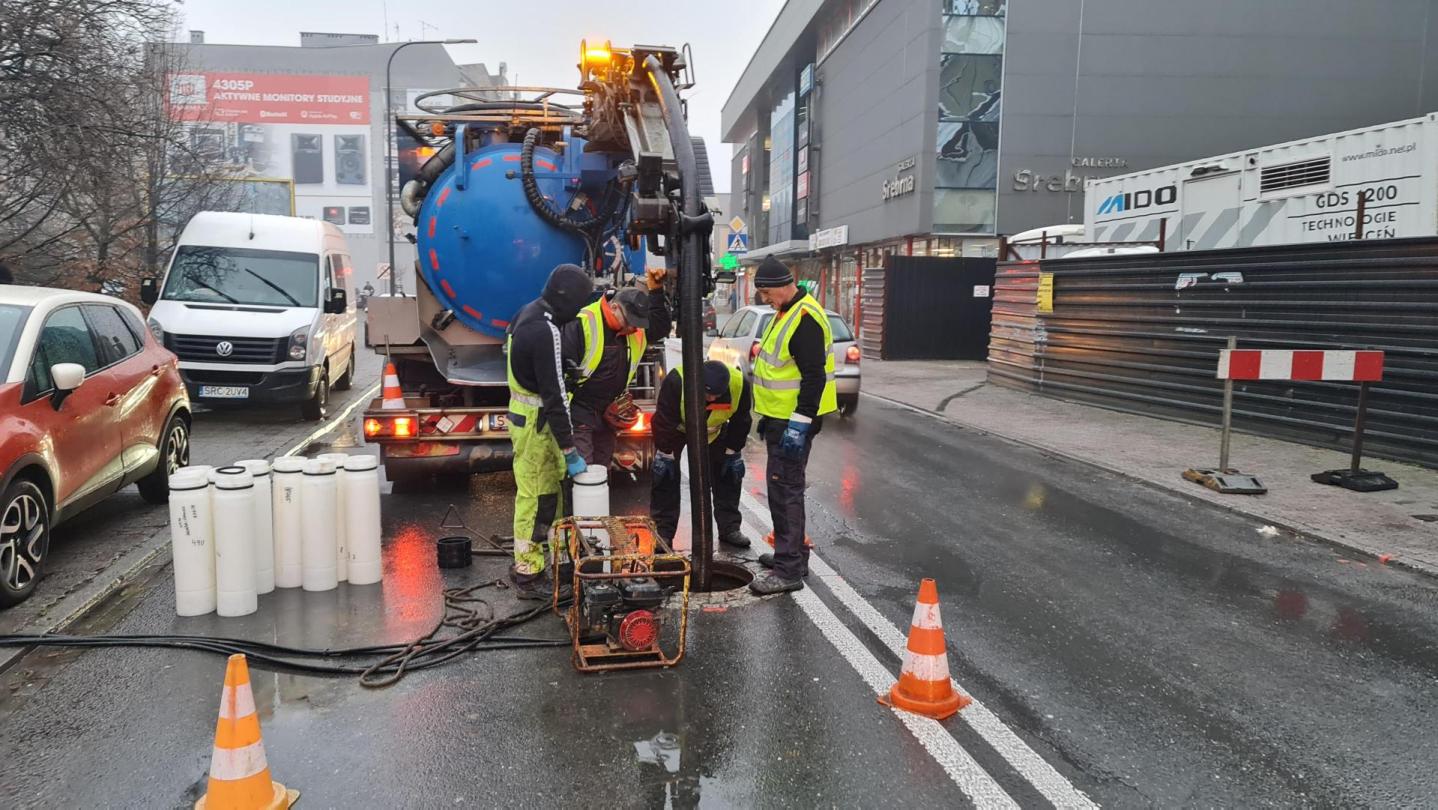

Opawska Street – one of Racibórz’s main arteries – is an urban corridor where traffic never stops. Shops, services, public transport and a constant flow of pedestrians make any excavation not only inconvenient but practically impossible without paralyzing the area.

For that reason we used a technology that allows work beneath the pavement without disturbing it, without noise, without blocking traffic and without changing traffic organization.

Scope of works:

As part of the project we installed a sanitary sewer connection:

- PP pipe Ø180 mm,

- 8.1 m bore,

- from manhole DN1200 to DN1000,

- design gradient: 7%,

- full trenchless technology – gravity drilling rig.

Such a steep gradient over a short distance required the highest precision in pilot guidance, a stable drilling trajectory and full control of direction. In Racibórz’s geological conditions — rich in gravel fractions and local cobbles — every metre of work must be executed with absolute certainty.

Our gravity drilling rig delivered the required geometry of the connection without any intervention in the road surface. Residents and drivers experienced no disruptions, and the works were completed quickly and in accordance with the design.

Why MIDO technology was critical?

- open trenching was not an option

- busy street with continuous load

- variable ground – gravels, sands, cobbles

- significant 7% gradient

- need to maintain full street functionality

The bore was executed without removing a single section of asphalt – no interference with traffic and no disturbance to the surroundings.